Bi-Oriented Film Line

- Bi-Oriented Film Line

- Battery Separate Film Line

- Carbon Fiber Battery Ion

- Shrink/Stretch Film Line

- Industrial Sheet&Film Line

- Optical Grade Sheet&Film Line

- Blown Film Line

- Recyclable Carbon Fiber

- Radio Frequency

- Natural Zeolite

Bi-Oriented Film Line(Simultaneous & Sequential)

Simultaneous Stretching MASIM

Patented technology for simultaneous biaxial stretching of films.

Ultra-thin clips

30mm MASIM clips. reduced distance & edge waste after stretching.

Applications

BOPI, CPI, PPS, BOPP capacitor Ultra-thin film, PTFE, High temperature resistance film

Technical film for communications : LCP, MPI

Mono-material packaging : BOPE

Traditional films : BOPP, BOPET, Optical films

Homogeneous air temperature & speed

Wet Process Battery Separator Films

: BOPE for Big stretching ratio and big MD relax to reduce final film shrinkage

High end Packaging : BOPA, Multilayer – High barrier film up to 13 layers

Customized film treatment : MD relaxation Oven to improve film MD properties

Stone Paper

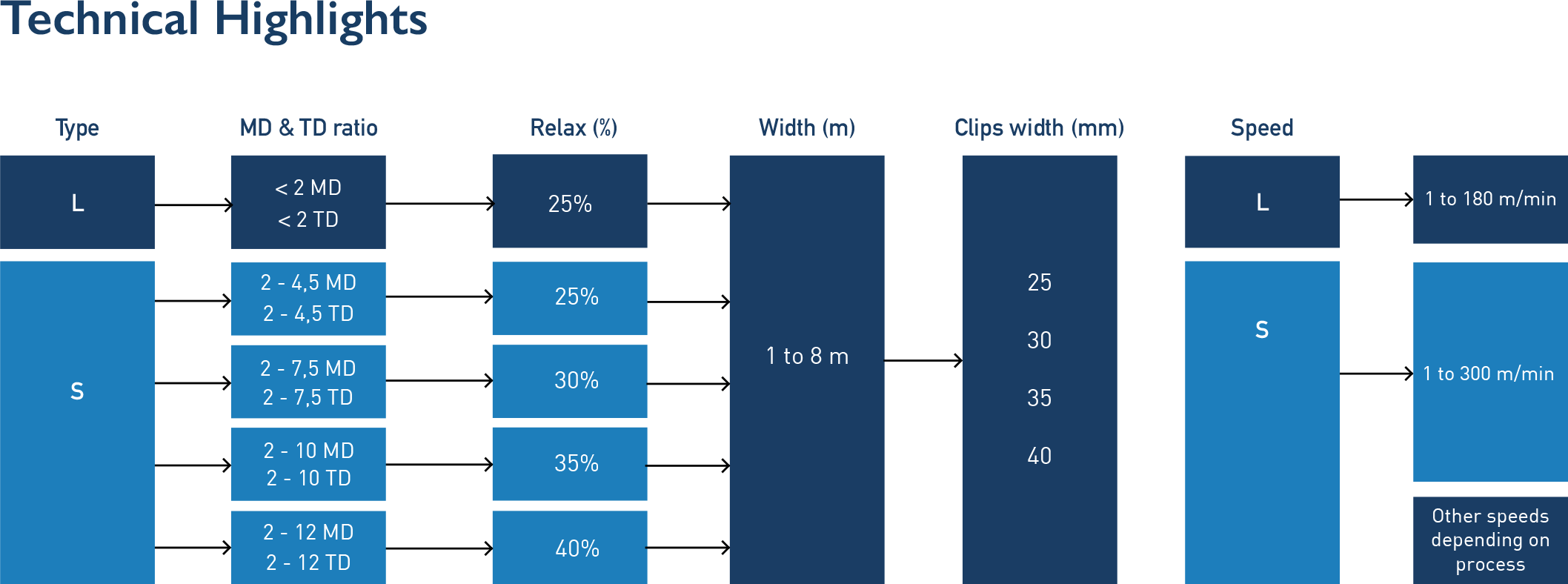

Sequential and Monoaxial Stretching (MDO, TDO)

Sequential Stretching Solutions – Machine Direction Orientation (MDO) and Transverse Direction Orientation (TDO) According to your process specifications and the properties you need to obtain, your film requires to be stretched either in Machine Direction, Transverse Direction, or both (sequential or monoaxial stretching).

MDOTDO

DRY PROCESS (PP, PP – PE – PP)

· Easy Process of Production

· Lower Cost of Investment

· Special Oven Design for Accurate Heat Transfer

· Thickness Down to 5µ

· Throughput up to 250,000,000m2/year